How to screen reliable EPDM plastic suppliers? Practical assessment criteria are here!

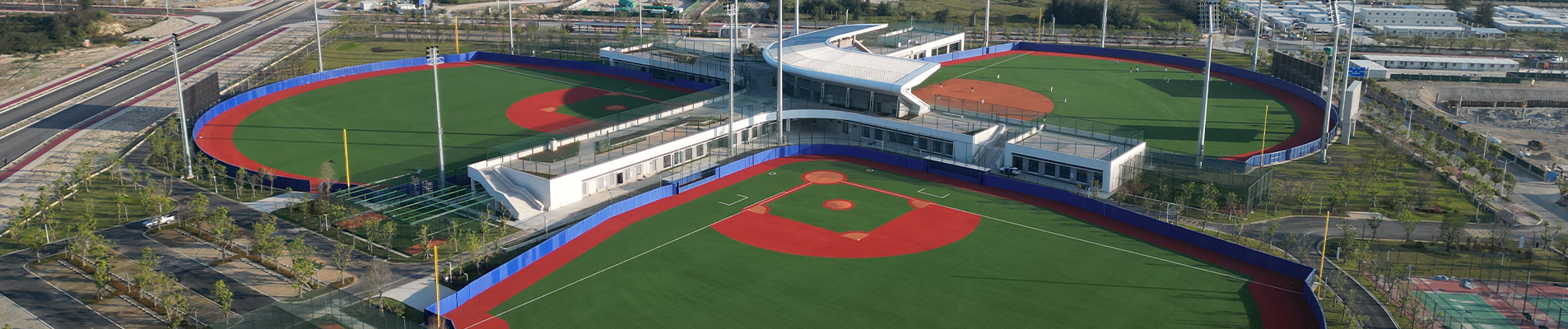

In EPDM plastic-related projects, from sports field construction to industrial applications, choosing a reliable supplier is of vital importance. The product quality, service level, pricing strategy and other aspects of the supplier all directly affect the final outcome of the project, cost control and subsequent maintenance. However, there are numerous suppliers in the market, with a mixed bag of quality. How can one select a suitable partner from them? The following will provide you with a detailed introduction to the evaluation criteria for reliable EPDM plastic suppliers.

1. Verify basic qualifications and certifications

Business License and Operating Permit: Legal and compliant operation is the foundation of cooperation. Ensure that the supplier holds a valid business license, and its business scope covers the production, sales and other related businesses of EPDM plastic. In some specific regions or projects, suppliers may also be required to have additional business licenses, such as relevant certificates related to environmental protection approval, to prove that their production activities comply with local regulations.

Quality management system certification: Like ISO 9001 quality management system certification, it is an authoritative recognition of the supplier's quality management capabilities. Enterprises that have obtained this certification indicate that they have established a complete quality control process throughout the entire process of product design and development, production, installation and service, which can effectively ensure the stability and reliability of product quality.

Environmental protection certification: EPDM plastic is often used in public places, such as school playgrounds and kindergarten activity areas, and its environmental protection performance has attracted much attention. Check whether the supplier has the ISO 14001 environmental management system certification and the environmental protection test reports of the products, such as the reports issued in accordance with standards like GB/T 20033.3-2006, confirming that the environmental protection indicators such as VOC emission and heavy metal content of the products meet the standards and are non-toxic and harmless. It will not cause harm to human health or the environment.

Industry-related qualifications: If the project has specific industry requirements, such as the professional contracting qualification for sports venue facilities engineering, it is a necessary qualification for suppliers undertaking the EPDM plastic track laying project of sports venues. This type of qualification reflects the supplier's technical capabilities and construction experience in the professional field, which can better ensure that the project complies with industry standards.

2. Examine the production capacity and scale

Production site and equipment: A large-scale and well-arranged production site is a sign that the supplier has sufficient production capacity. Advanced production equipment, such as high-precision EPDM granule production equipment and automated batching and mixing systems, not only enhance production efficiency but also ensure the consistency of product quality. For instance, with advanced mixing equipment, EPDM plastic raw materials can be mixed more evenly, enhancing product performance.

Capacity assessment: Understand the monthly output, annual output and other capacity data of the supplier, and in combination with the requirements of your own project, determine whether they have the ability to supply products on time and in sufficient quantities. For large-scale projects, a stable supply of production capacity from suppliers is the key to the smooth progress of the project, avoiding project delays due to insufficient supply.

Raw material reserve and management: High-quality suppliers will attach great importance to the reserve and management of raw materials. A sufficient inventory of raw materials can cope with market fluctuations and sudden order demands. Meanwhile, standardized storage conditions for raw materials, such as the classified storage of EPDM particles, adhesives, additives, etc., to prevent mixing of materials, and the warehouse being equipped with moisture-proof and sun-proof measures, can ensure that the quality of raw materials is not affected, thereby guaranteeing the quality of the final products.

3. Evaluate product quality

Sample testing: Request product samples from suppliers and conduct multi-faceted tests. In terms of physical properties, the wear resistance is tested to simulate actual usage scenarios. After a certain number of tests with a friction testing machine, the wear condition of the sample surface is observed. Test the anti-slip performance by using a professional coefficient of friction meter to measure the coefficient of friction in both wet and dry conditions to ensure compliance with safety standards. Check the elastic recovery rate. By using specific pressure testing equipment, measure the sample's ability to return to its original state after applying pressure. A good elastic recovery rate can provide users with a comfortable experience and reduce sports injuries.

Quality control process: Inquire with the supplier about the quality control links in the production process, from the incoming inspection of raw materials, to the random inspection of semi-finished products during the production process, and then to the full inspection or random inspection of finished products. Each link should have strict quality control standards and procedures. For instance, when raw materials enter the factory, the purity and particle size distribution of EPDM particles are tested. During the production process, the hardness, tensile strength and other indicators of the products are monitored in real time. During the finished product inspection, a detailed examination is conducted on the appearance, dimensional accuracy and other aspects of the products.

Quality traceability system: Suppliers with a complete quality traceability system can quickly locate the problem links, such as raw material batches, production equipment, operators, etc., when product quality issues occur, facilitating timely improvement measures and the recall or handling of problem products to safeguard customer rights and interests.

4. Consider the service level

Pre-sale service: A professional pre-sale team can provide customers with comprehensive consulting services. For instance, based on project requirements, recommend suitable EPDM plastic product models and specifications to customers, and provide detailed technical solutions, including construction techniques and suggestions for base treatment, etc. In communication, be able to clearly answer customers' questions regarding product performance, price, transportation and other aspects.

After-sales service: Clearly define the after-sales service content of the supplier, such as the warranty period, the commitment to maintenance services during the warranty period, and the response time for maintenance, etc. High-quality suppliers will provide free repair or replacement for any damage caused by product quality issues within the warranty period. We can respond to the problems raised by customers within 24 hours.