How to choose the lawn for a croquet court? Remember these 3 points and you won't fall into traps!

When choosing a croquet court turf (the mainstream being artificial turf), the key points focus on three aspects: the core parameters of the grass fibers, structure and durability, and compatibility with scenarios and supporting guarantees. By precisely controlling these aspects, one can avoid the vast majority of purchasing traps and balance sports performance, safety and economy. The following is a detailed analysis and practical guide.

Core Parameters: The material, height and density of the grass fibers determine the performance of the movement

1. Grass filament material: The mainstream choice is PE monofilament, which combines softness and wear resistance. PP is stiff but slightly hard, making it suitable for special scenarios. The combination of PE and PP offers a high cost performance. Professional field selection of high-purity PE monofilament (anti-lodging, low ball rolling resistance); The leisure area can be selected with a mixture of PE and PP.

2. Grass filament height: 15mm in professional competition venues (common standard of WBF); Community leisure area: 10-15mm

3. Grass fiber density: Sand-filled type ≥ 33,000 clusters/square meter (in combination with quartz sand); No-filling type ≥ 63,000 clusters per square meter

Structural quality: The base fabric, back adhesive and filling determine the service life

This is the key to the lawn's tear resistance, anti-shedding and long-term stability, which directly affects maintenance costs and safety.

Base fabric and backing adhesive: Double-layer composite base fabric (PP woven fabric + mesh fabric) is preferred, which is tear-resistant and suitable for foundation settlement. The back adhesive can be selected from styrene-butadiene latex or polyurethane adhesive, which has strong adhesion, is environmentally friendly and odorless. Avoid pitfalls: Refuse single-layer thin base fabric and low-quality pungent glue, as they can easily cause large-scale shedding of grass fibers.

Filling selection (sand-filled type) : Quartz sand particle size 0.2-0.6mm, filling amount 4-6kg/㎡ (up to 8kg/㎡ for professional courts), used for fixing grass fibers and stabilizing ball paths. Avoiding pitfalls: Using sea sand or sand with many impurities can easily corrode the base fabric and affect the uniformity of the ball speed.

No-filling type: It is self-supported by high-density grass fibers and is suitable for low-frequency usage scenarios. Maintenance is more convenient, but it is necessary to ensure that the grass fiber density is ≥ 60,000 clusters per square meter to prevent the grass fibers from falling over.

Adapt scenarios and provide supporting guarantees to avoid the situation where "the parameters are right but the usage is wrong"

By integrating the frequency of use, the target audience and the construction conditions, and combining the foundation with after-sales service, it is necessary to ensure long-term usability.

1. Scene matching

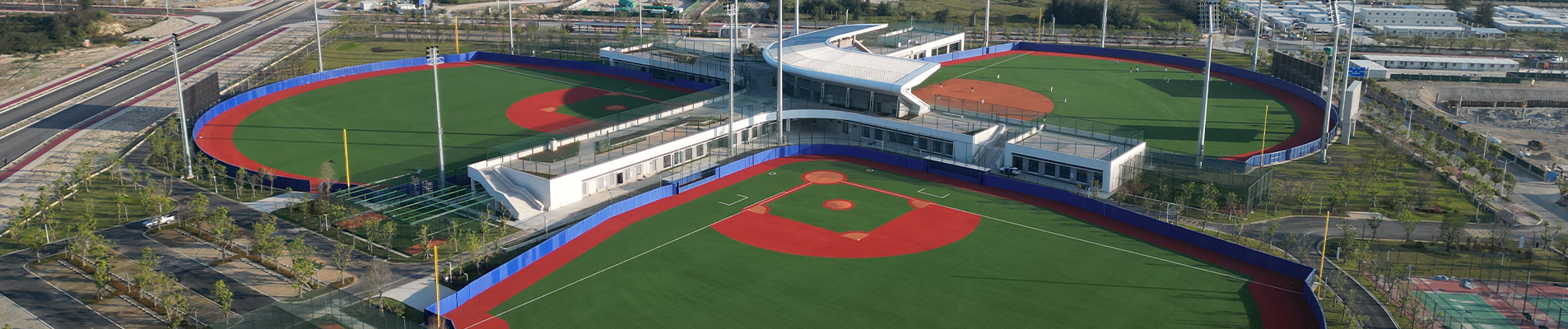

· Professional competition venue: Select PE monofilament, 15mm height, ≥ 69,300 clusters /㎡ density, combined with sand-filling process to ensure that the ball path deviation is ≤2°, meeting the competition standards.

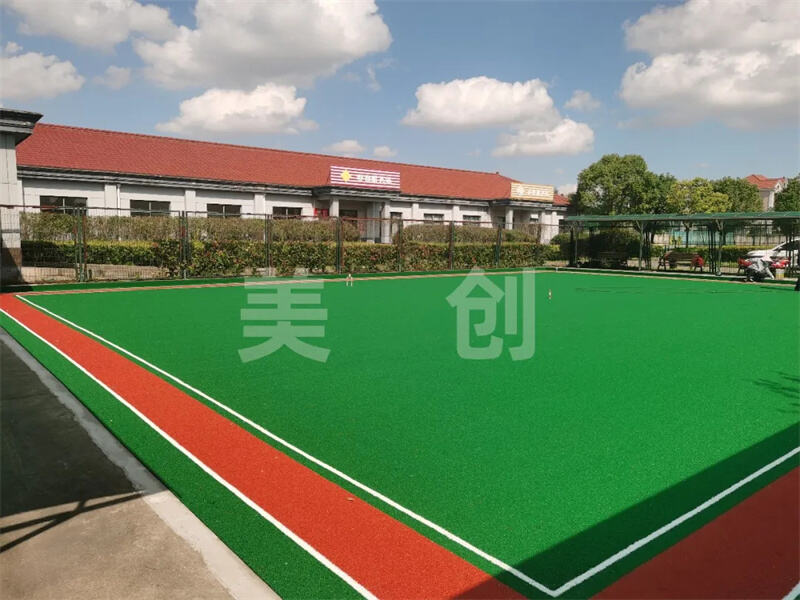

· Community/nursing home facilities: Prefer non-filling type or mid-end sand-filled type. The grass fibers can be treated with round ends. The bottom fabric should be thickened to enhance anti-slip and shock absorption, preventing injuries to the elderly.

2. Supporting facilities and construction

· Basic requirements: The flatness error of the cement foundation should be ≤3mm (5-meter straightedge), the lateral slope of the site should be 8‰, and the longitudinal slope should be 5‰ to ensure smooth drainage.

· Construction and after-sales service: Select a team with the qualification for sports ground paving, and the joint error should be ≤2mm. Request a warranty (high-quality lawns have a lifespan of 6 to 8 years), and clearly specify the after-sales maintenance terms.

3. Safety and Environmental Protection: Request the test report, with a focus on checking formaldehyde emission ≤0.1mg/m³, UV resistance for over 5000 hours, wear resistance ≥5000 revolutions without pilling, to ensure the health of users.

Quick selection suggestions

· Professional competition: PE monofilament + 15mm + sand-filled + high-density + double-layer base fabric + polyurethane adhesive, with a qualified construction team.

· Community leisure: PE+PP blend + 10-15mm + medium density + no filling/light sand filling + composite base fabric, cost control.

· Nursing home: PE monofilament + 15mm + no filling + round-head grass filament + thickened base fabric, emphasizing safety and easy maintenance.