Analysis of the advantages of EPDM plastic materials: MCG Raw material Manufacturing Factory & Solution Service Provider offers you a more superior solution

Among the construction of various sports venues, EPDM plastic running tracks have stood out and become the favorite of many schools, sports venues and community fitness places. It not only has outstanding material performance advantages, but also, when combined with the one-stop service provided by a professional construction team, can create high-quality and long-lasting sports venues. Now, let's take a deep dive into the unique charm of EPDM plastic.

(1) Green and environmentally friendly, health first choice

EPDM plastic running tracks are mainly composed of ethylene propylene diene monomer (EPDM) rubber particles. This material itself is non-toxic and odorless, and will not release harmful gases such as formaldehyde and benzene, as well as heavy metal substances during production and use. In the current era where environmental protection and health are increasingly valued, this feature makes it particularly suitable for densely populated places such as schools and kindergartens. For instance, after a newly-built kindergarten adopted an EPDM rubber track, parents no longer need to worry about their children coming into contact with toxic substances during sports. Children can run and play freely on the playground, ensuring safety.

(2) Super weather resistance and long-lasting durability

Ethylene propylene diene monomer (EPDM) rubber has excellent resistance to ultraviolet rays, ozone and high and low temperatures. Whether it is the scorching summer, the biting winter, or long-term exposure to sun and rain, EPDM plastic running tracks can maintain stable physical properties and are not prone to problems such as fading, cracking, and deformation. Take the playground of a certain middle school in the south as an example. The EPDM plastic track laid there remains bright in color and elastic as before after years of use, and can continuously provide a high-quality venue for students' sports activities.

(3) Good elasticity and motion protection

The good elasticity of the track can effectively absorb the impact force during sports, just like installing "shock absorbers" for the joints and muscles of athletes. In sports such as running and jumping, it can significantly reduce the pressure on the knees, ankles and other parts, and lower the occurrence rate of sports injuries. For professional athletes who frequently engage in sports training and ordinary people who exercise daily, this protective effect is of vital importance, making sports safer and more comfortable.

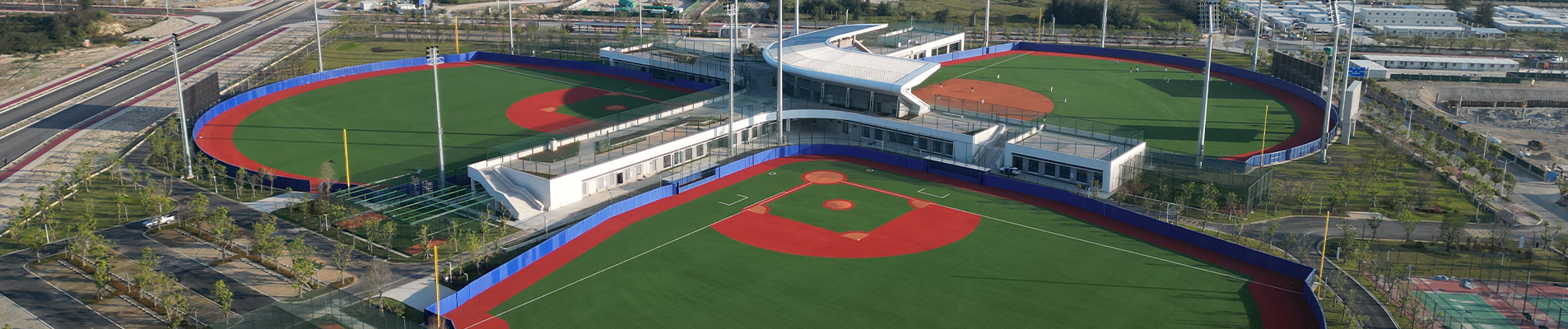

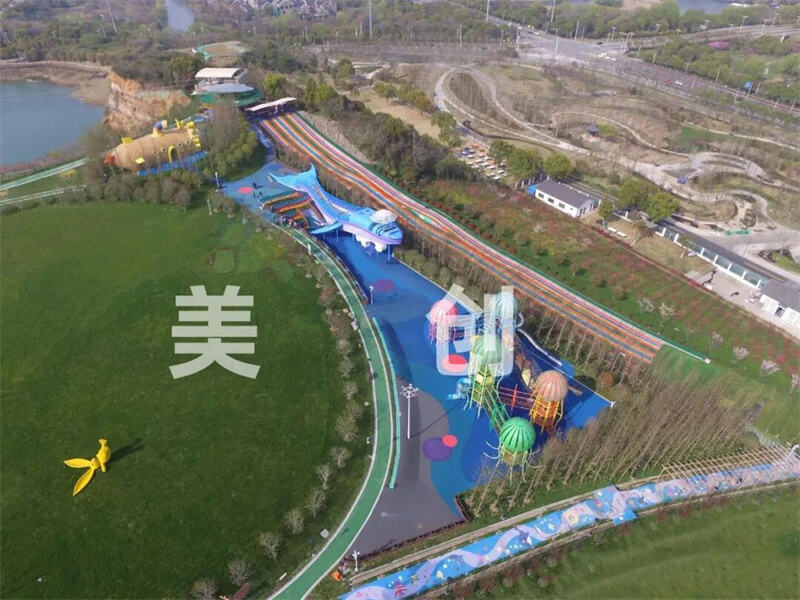

(4) Rich in color, beautiful and practical

The colors of EPDM plastic running tracks are very rich, with a variety of bright colors such as red, blue, green and yellow for you to choose from. They can also be combined with multiple colors according to the design requirements of the venue to draw unique patterns and signs. This not only adds vitality and beauty to the sports field, but also makes the functions of different sports areas more distinct through color zoning. For instance, the running track, football field, basketball court and other areas on the school playground can be clearly divided by color, enhancing the practicality and functionality of the field.

(5) Anti-slip, wear-resistant, safe and durable

The special granular structure on its surface provides sufficient friction. Even in damp environments, such as after rain, it can effectively prevent slipping and ensure the safety of athletes. At the same time, it also has excellent wear resistance, can withstand frequent use by a large number of people and the friction of sports equipment, has a long service life, and reduces the cost and trouble caused by frequent venue changes.

Professional construction services, quality guaranteed

(1) Precise planning and preparation before construction

Professional construction teams will conduct a comprehensive investigation of the site before construction, including the flatness of the ground, the bearing capacity of the foundation, drainage conditions, etc. Based on the survey results, formulate a detailed construction plan and take preventive measures in advance to deal with possible problems. For instance, if the foundation is uneven, it will be leveled in advance. If the drainage is not smooth, the drainage design will be optimized to ensure that the runway will not be affected in use by water accumulation after its completion.

(2) Standardize the construction process and strictly control each level

1. Base treatment: Thoroughly clean the ground of debris, oil stains, etc., and grind and repair the concrete or asphalt base to meet the specified flatness and strength requirements. At the same time, do a good job in the construction of the waterproof layer to prevent groundwater seepage and affect the service life of the runway.

2. Elastic layer laying: Mix EPDM particles with polyurethane glue in an exact ratio (usually between 2:1 and 3:1) and stir evenly. Then, use professional equipment to spread it, and control the laying thickness well. Generally, the thickness of the elastic layer is between 8 and 13mm. During the paving process, mechanical or manual compaction is adopted to ensure the density and uniformity of the elastic layer.

3. Surface layer construction: After the elastic layer has cured, the surface layer construction is carried out. Mix the colored EPDM particles with the glue again and form a surface layer by spraying or spreading. The thickness of the surface layer is generally 2-3mm. During construction, attention should be paid to uniform color and no obvious seams to ensure the aesthetic appearance and anti-slip performance of the track.

4. Marking and positioning: According to the standard dimensions and usage requirements of the sports field, professional measuring instruments are used for precise measurement and positioning, and then high-quality polyurethane marking paint is applied for marking. The lines should be clear, straight and of uniform width, with errors strictly controlled within the prescribed range, providing accurate sports identification for athletes.

Thoughtful maintenance and guidance after construction

After the construction is completed, the professional team will provide the customer with a detailed maintenance manual to guide the daily maintenance work. For instance, inform the customer to regularly rinse the runway with clean water and avoid using corrosive cleaners such as strong acids and strong alkalis. For areas with severe wear, local repairs should be carried out in a timely manner to extend the overall service life of the runway. In addition, regular follow-up services will be provided to inspect the usage of the runway and answer customers' questions.